Home — Services: Manufacturing supervision

Manufacturing

supervision

Control and data acquisition for Maguire blenders

We developed a software that collects data from Maguire blenders and provides a way to set their settings. Data are stored in MS SQL, so it is possible to connect them with other systems.

Functions:

- Acquisition of batch and alarm data

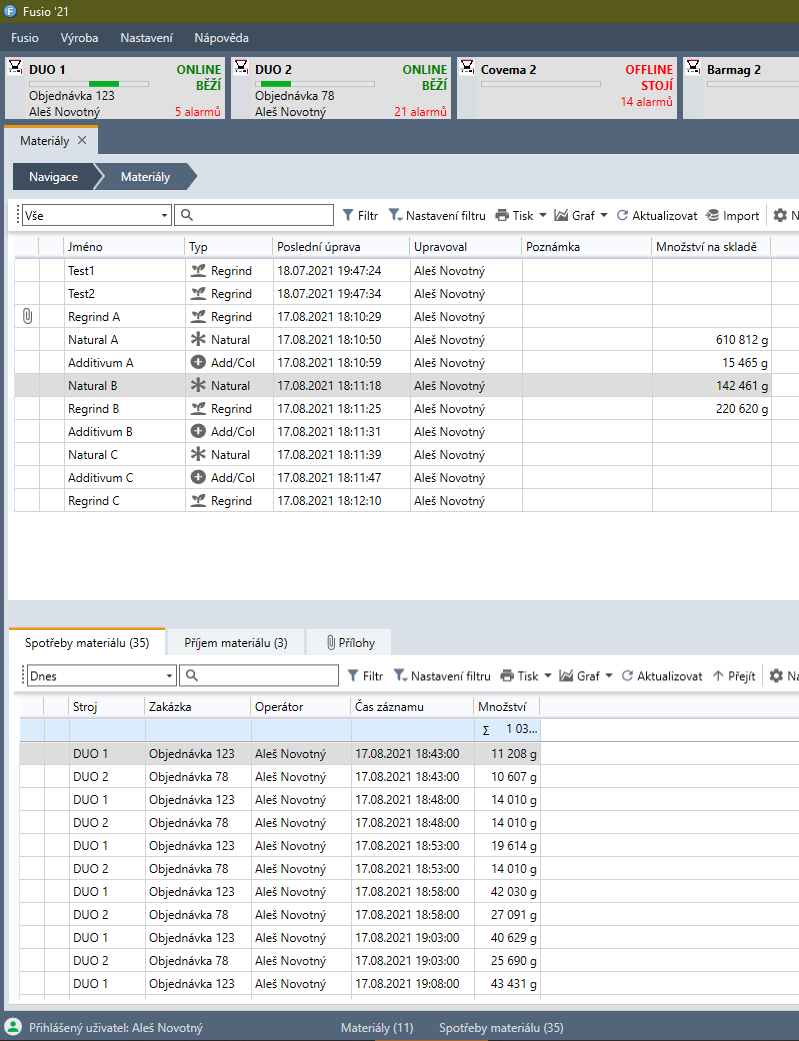

- Materials database management

- Recipe database management

- Supports both MLAN and Ethernet

- Supports large number of clients (>100)

- Application runs as Windows service

Integration into Fusio

Our customers often did not want to invest so much energy and money into complicated expansion of their current MES, or they do not have such system. In such case we provide our own solution, which is integration into the Fusio system.

In cooperation with Ants company, we integrated functions from previously mentioned “core” to their Fusio system. This system is usually deployed as support information system that can be flexibly configured. Thanks to its easy configuration, that is open to customers, it serves as a glue for holes in company processes and workflows.

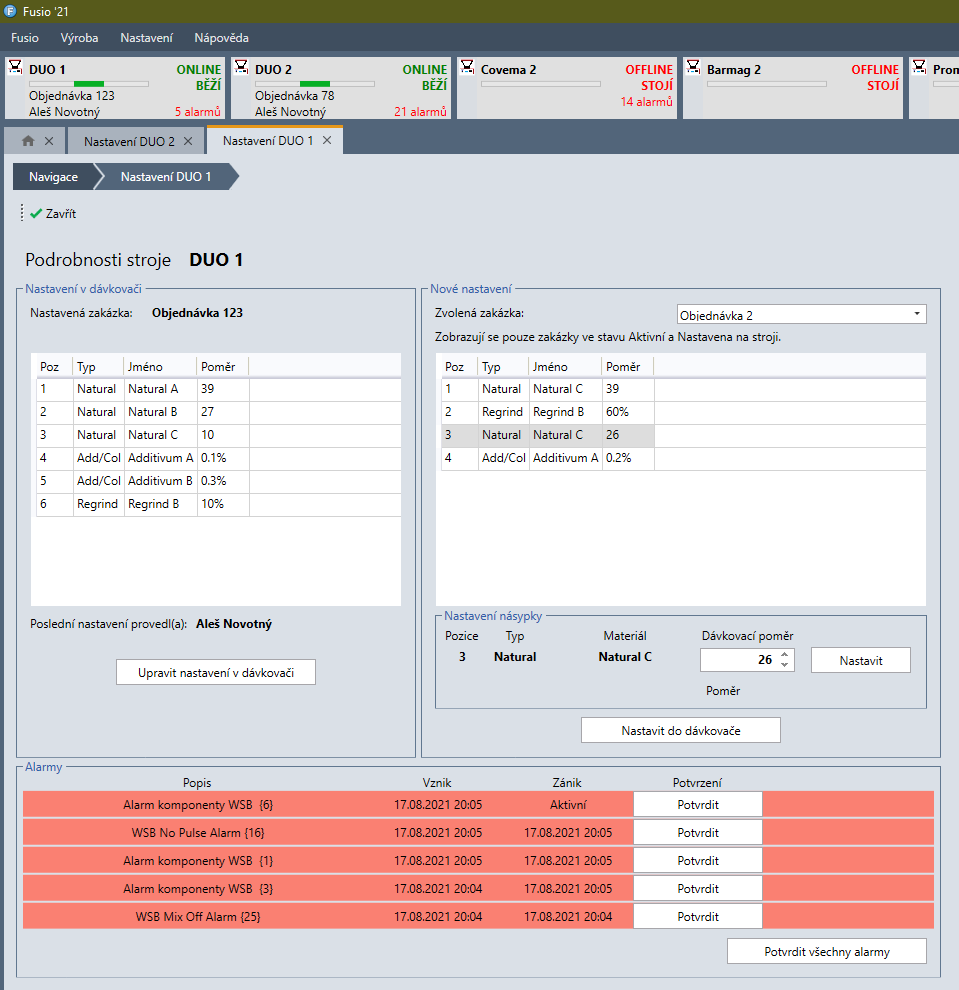

In its basic configuration you can define materials, create recipes as combinations of materials and create a job for specific machine. Then you can set this job into the machine and its blending data will be paired with defined materials. You can then supervise consumption of materials depending on machines/jobs/time/operator. There is also a form for inputting receiving of materials, so it is possible to monitor the current amount of stored materials. With data from blending, you can detect manufacturing problems early.

Fusio natively offers these functions:

- High modularity = low cost for implementation of new functions

- All records can be filtered with both simple and very complicated criteria

- All data can be plotted to charts

- Send email reports based on events

- Users can create printing templates

- Function’s access is based on roles (Base user, department leader, admin)

- Import from .csv, export to .xlsx

- All records have access and editing history

During writing of settings to machine you can still fine-tune hopper settings. You can also view and acknowledge blender’s alarms.

More info provided here: Informační systém Fusio pro workflow firemního provozu (Czech only)

Some info is provided only in Czech. If you are interested in this solution, feel free to contact us!

SimasWeb

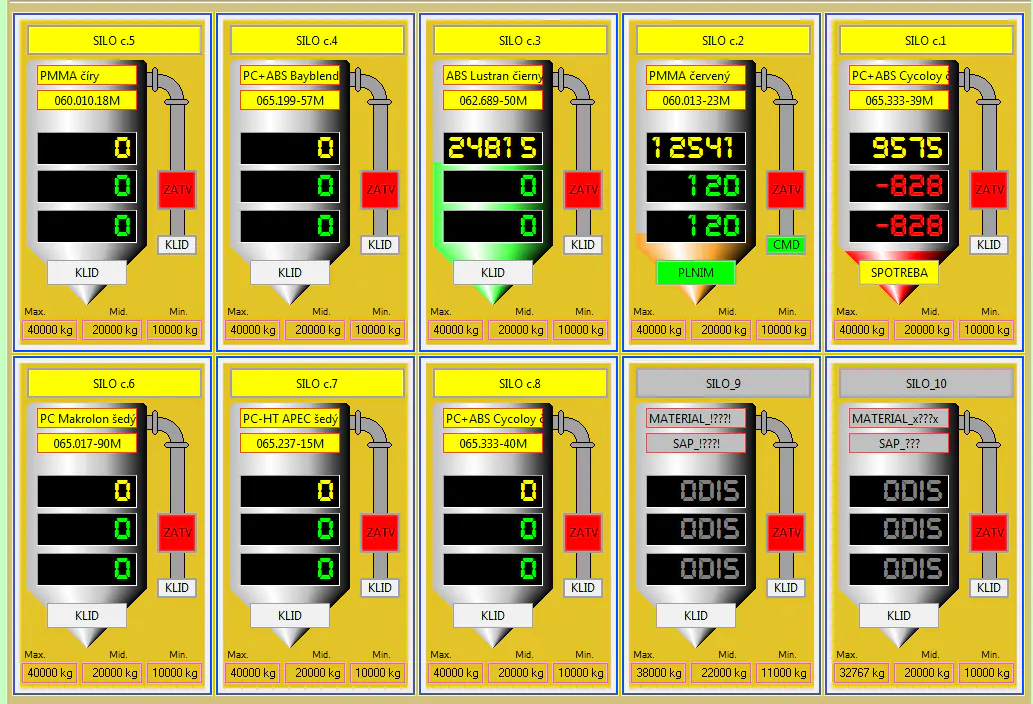

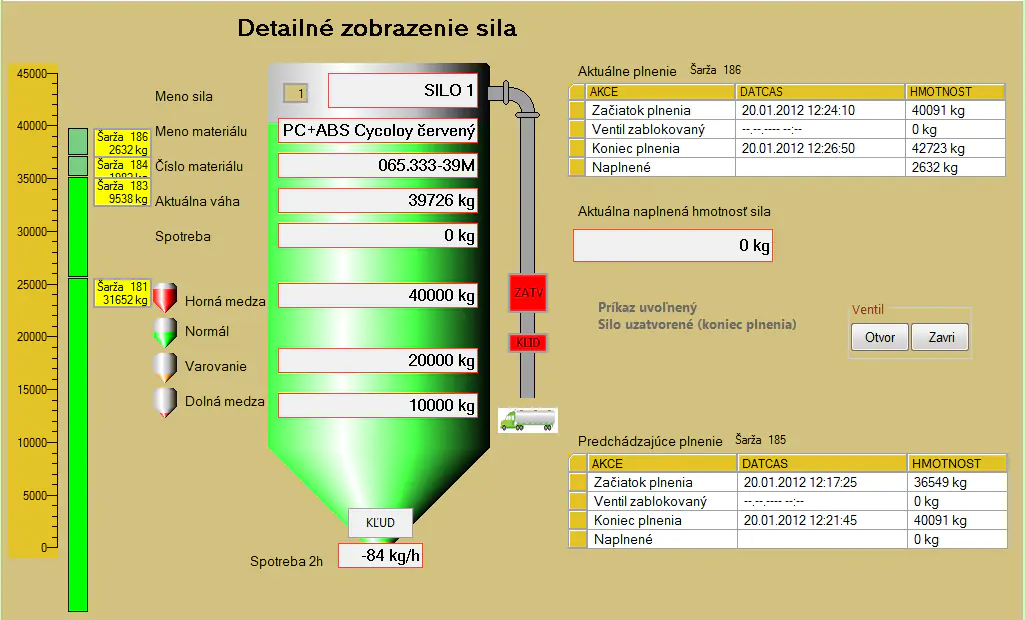

We developed SCADA system for silo filling and storage management.

Logistics worker can cooperate with transport driver during silos filling. This will ensure that correct silo is being filled and with correct pressure.

This system provides overview of all the single batches that were filled into the silo. You can create a protocol about the filling.

And so much more

We can create a custom application that suits your best needs. We specialize on:

Control WEB application

Universal SCADA/HMI system, that provides many ways to control, visualize and collection of data.

PLC applications

Custom PLC application for nearly any form of control and data acquisition

.NET Applications

Developments of data processing applications, server backends or user interfaces.

Mobile applications

Multiplatform development for Android, iOS. Including deployment on Google Play and App Store.

We focus on development and implementation of control systems, mainly in electro energetics, manufacturing, and IT.

Services

Navigation

Quick contact

+420 511 112 864

info@aurox.cz